EGG CHICKEN ORIENTED ORGANIC MANURE MANURE MANUFACTURING

This issue is have to be well known by the investors of egg chicken industry that; a dangerous and having some bad effects to the environmet material how to become a gaining profit from it which name si manure. However the costs of manufacturing the organic manure from the egg chicken manure is very high in the systems using right now. This type of manure's process of transformation to the organic manure takes long time. So the costs are effected by this timing problem.

This issue is have to be well known by the investors of egg chicken industry that; a dangerous and having some bad effects to the environmet material how to become a gaining profit from it which name si manure. However the costs of manufacturing the organic manure from the egg chicken manure is very high in the systems using right now. This type of manure's process of transformation to the organic manure takes long time. So the costs are effected by this timing problem.

The nutrition elements in the chicken manure's and its process of become ready to usage of the plants with the consumption value of %45 in first month from throwing on the ground has to be well studied. We are surely knoe that, %35 of the feeds wasted in the chickens manure with no harm and this makes the manure more valuable according to its efficiency. Time to time we are aconsidered that tihs wastes at least some part of or all of it must be gained back.

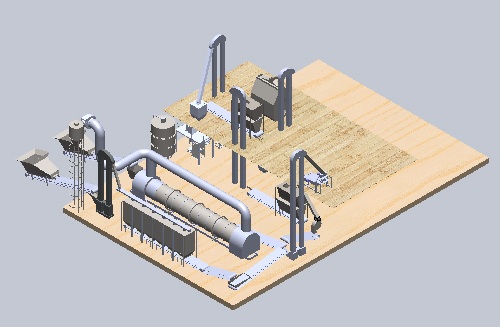

We are get the chickens manure to be rady for marketting as an organic manure througt to our proceeding system which also designed by us on the capacity of 1,000,000 chickens manure daily. Also we are reach on this system have %50 cheaper than the other systems.

In our system 150 Tons of manure processing easily on one horizontal drying oven. That menas approximately 1,000,000 chicken manures. For reaching this values we developed the production system.

In the past, when we looked to the chickens manure and say "how to get dry this manure", now we are able to look and say "How much we can earn from it". The usage of the organic manure is increasing year to year. Because its prices are lower than others, and organic foods investors are increasing. In nezt 5-10 years the organic manure gets very importance and brings many incomes.

The truth is who is started an investment on this sector, he will have much income for himself. On the future maybe there are more investors make investments on this sector and the percentage of profits can become normal. The raw material is on your hand and keep rising daily.

The ratio of egg chicken manure C /N is 13, and ther is not necessary fermentation process. After the faster drying process the humidity of the manure has to be decreasing from %76-%78 values. The humidity decreasing on dust form, helps us less bad smell and more longer saving time without any corruption. If the production made on the form of pellet, first drying process could outputs more humiditied manure, because pelletting process heats the manure and providing necessary humidity lost for organic manure.

The average value of manure which handled from one chicken in Summer and Winter is approzimately 150 Gr. Egg Chicken oriented organic manure could manufactured with %50 additive addings in it. On little rainy areas and no irrigating areas there must be some additive materilas should adding into the this manure.

WHEN ADDITIVE MATEARIALS ADDING IN THE EGG CHICKEN ORIEBTED ORGANIC MANURE, MUC MORE DEMAND IS FULLFILLED AND THE QUALITY OF THE MANURE IS INVREASED. THE EGG CHICKEN MANURE IS THE MOST SUITABLE MANURE FOR PRODUCING BIOGAS. EFFICIENCY OF GAS ON THIS MANURE IS VERY HIGH.